ACTIVITIES

Cutter-suction dredgers

The company owns 2 suction dredgers:

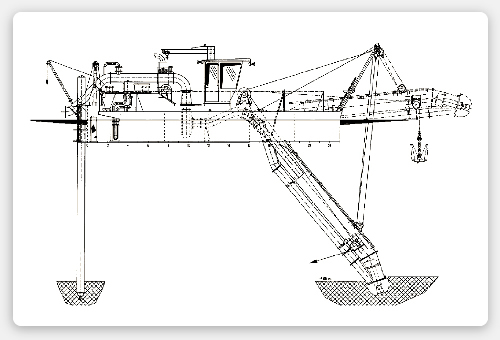

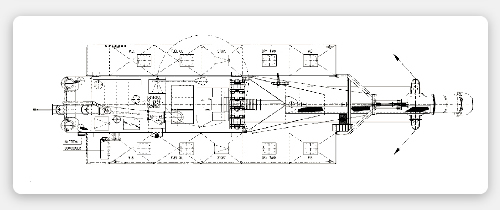

1. Cutter-suction dredger IHC, Beaver type 600 with a built-in cutter; power of diesel engine is 630 hp. Maximum depth of excavation is 9 m. The dredger can be disassembled, transported to the location and shipped to the water by auto cranes.

The cutter-suction dredger is performing excavation on the following ways:

- The end of cutter-suction pipe is placed on the profile to be excavated. The thickness of the layer to be removed in one pass depends on the type of material. The excavation is performed in required number of passes until the defined depth is reached.

The mixture of excavated material and water (in ratio 1:5 to 1:10), is sucked by the centrifugal pump and transported through a system of floating pipelines to the place of disposal, maximum 3000 m away.

The dredge is moving along the trench line using two anchors and two pylons. Considering the technology of the dredger and the type of material to be excavated, the tolerance for excavation level ranges + / - 20 cm.

The excavated material can be disposed into the river or into the cassettes that are designated by the Investor.

2. Cutter-suction dredger MB30 can be easily transported from one work place to another. It has similar operating performances as the Beaver 600. Installed power is 180 hp, and maximum depth of excavation is 10 m. It has maximum disposal distance of 400 m.